Kala-goysyada Balaadhinta/Isgoysyada Balaadhinta Dharka

Codsiga Isku-goysyada Balaadhinta Maryaha Aan-Birta ahayn

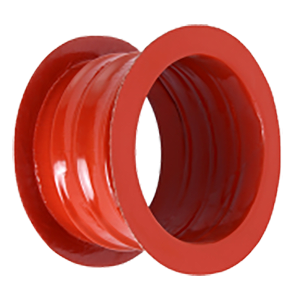

Balaadhinta Fabric-ka-goysyada La-goysyada ee dib-u-celinta waa nooc cusub oo kala-goysyada ballaarinta aan biraha ahayn. Faa'iidooyinka caadiga ah waa miisaan fudud, jilicsan, hermetic, heerkulka shaqada oo sarreeya, ka hortagga daxalka, heerka magdhowga weyn iyo rakibida fudud. Waxay ku habboon yihiin isku xirka dabacsan ee u dhexeeya marawaxadaha hawo-qaadista ee kala duwan, tuubooyinka iyo tuubooyinka; waxay magdhabi kartaa qallafsanaanta kulaylka ee tuubooyinka waxayna sii deyn kartaa cadaadiska tuubada; hoos u dhigo ama daciifiyo gariirka dhuumaha; oo fududeeya rakibidda nidaamka oo dhan.

Isku-goysyada Balaadhinta Maro-Jingadaha way ka duwan yihiin kuwa caadiga ah ee balaadhinta aan biraha ahayn. Waxay ka samaysan tahay hal lakab ama lakabyo badan oo caag iyo dhar ah, oo lagu daboolay heerkul sare iyo cadaadis; rogaal-celinta waa la rogaa oo halmar baa loo qaabeeyey iyadoo leh farsamooyin gaar ah, taas oo ka duwan farsamada soo saarista kala-goysyada ballaadhinta dhar-dhaqameedka ----xabagta, tolida, daboolka iyo riixida flange. Farsamooyinka gaarka ah ayaa ka dhigaya kala-goysyada ballaarintayada inay ka gudbaan kala-goysyada ballaarinta dhaqameed ee dhibcaha daciifka ah sida kuwa aan si adag loo daboolin, ma aha hermetic, daadinta, culus, adagtahay rakibidda iyo dayactirka.

Isku-xidhka Balaadhinta Dharka Jiingadaha ah waxay ku xidhmaan flanges oo leh lakabka caagga ah ee u gaar ah ee rogroga, xidhiidhku waa hermetic; waxayna sii wadi kartaa cadaadiska shaqada ugu badnaan 2MPa. Saamiga isku-buuqa axial-ka, radial-ka iyo wareejinta wareegta ayaa aad uga wanaagsan kala-goysyada fidinta dhaqameed. Isku-goysyada Balaadhinta Dharka Waddooyinka ah waxay aad ugu habboon yihiin taageerayaasha hawo-qaadista, tuubooyinka si loo yareeyo gariirka nidaamka, buuqa iyo walbahaarka. Waxay yihiin qaybaha ugu fiican ee ay tahay inaad u lahaato nidaamkaaga.

Waxaan isticmaalnaa noocyo kala duwan oo dhar ah si aan u samayno kala-goysyada ballaarinta iyadoo loo eegayo shuruudaha farsamo ee macaamiisheena iyo jawiga codsiga, sida caag silikoon, caag fluorine, Ethylene-Propylene-Diene Monomer (EPDM).

Codsiga lagu taliyay

● Warshadaha geedi socodka

● Warshadaha kiimikada

● Warshadaha kiimikada

● Warshadaha dawooyinka

● Warbaahin kiimikaad, sun ah, khatar ah

● Hadhaaga iyo qashinka oo la gubo

● Calcination

● Dhimista

● Warshadaha saliidda iyo gaaska

● Tignoolajiyada sifaynta

● Farsamada warshadda korontada

● Warshadaha saxarada iyo waraaqaha

● Wax-soo-saarka birta iyo farsamaynta

● Warshadaha sibidhka

● Tubooyinka gaasta hargabka

● Kuleyliyaha gudaha iyo meelaha laga baxo

● Dhuumaha oo la geliyo

● Khadadka habraaca

● Duubista

● Warshadaha leh shuruudo sare

Faa'iidooyinka

● Sii daynta wasakhda oo yaraatay

● Hawlgal ammaan ah

● Hoos u dhac weyn oo ku yimid isticmaalka tamarta aasaasiga ah

● Cimri dheer oo adeeg, xidhid hoose

● Waqti dhimis la saadaalin karo

● Loo heli karo dib-u-habaynta nidaamyada jira

● Debacsanaan wanaagsan

● Iska caabin kiimiko oo sarreeya

● Luminta kulaylka oo yaraatay

● Xoogaga falcelinta ugu yar

※ Loo habeeyay si ay ugu habboonaato xaaladaha shaqada dhabta ah iyo agabka marka la codsado.

| Qalabka Dharka | Hawlaha caddaynta cimilada | Hawlaha jirka | Hawlaha kiimikada | heerkulka shaqada | Uma aha | |||||||||||||||||

| ozene | oksaydh | iftiinka qorraxda | shucaac | dhumucda dharka | kala duwanaanshaha cadaadiska | saamiga cadaadis axial (%) | saamiga axial stretch (%) | beddelka shucaaca (%) | ku haboon dareereyaal | Hot H₂SO₄ | Hot H₂SO₄ | HCL kulul | HCL kulul | Anhydrous ammonia | NaOH | NaOH | shaqaynaysa kala duwanaanta heerkulka | Ugu badnaan joogto ah heerkulka shaqada | ku meel gaar ah heerkulka shaqada | |||

| dharka+lakabka gaaska | Cadaadis togan | Cadaadis xun | <50% | >50% | <20% | >20% | <20% | >20% | ||||||||||||||

| EPDM caag (EPDM) | wanaagsan | wanaagsan | wanaagsan | wanaagsan | 0.75 ~ 3.0mm | max34.5 daq14.5 | max34.5 daq14.5 | 60% | 10-20% | 5-15% | gaasta daxalaysa dareerayaasha organic gaaska guud | ku haboon (wanaagsan) | celcelis ahaan ama faqiir | celcelis ahaan | miskiin | ku haboon (wanaagsan) | ku haboon (wanaagsan) | ku haboon (wanaagsan) | -50 ~148 ℃ | 148℃ | 176℃ | Hydrocarbons Aliphatic Hydrocarbons caraf udgoon |

| Rubber Silikoon (SL) | wanaagsan | wanaagsan | wanaagsan | celcelis ahaan | 0.6 ilaa 3.0mm | max34.5 daq14.5 | max34.5 daq14.5 | 65% | 10% ilaa 25% | 5% ilaa 18% | gaaska guud | miskiin | miskiin | miskiin | miskiin | miskiin | ku haboon (wanaagsan) | celcelis ahaan | -100 ~240 ℃ | 240℃ | 282℃ | Saliida xalisa aashito alkali |

| Chlorosulfonated caag polyetylen ah (CSM/Hypalon) | wanaagsan | wanaagsan | wanaagsan | wanaagsan | 0.65 ~ 3.0mm | max34.5 daq14.5 | max34.5 daq14.5 | 60% | 10-20% | 5-15% | gaasta daxalaysa dareerayaasha organic gaaska guud | ku haboon (wanaagsan) | celcelis ahaan | celcelis ahaan | miskiin | celcelis ahaan | ku haboon (wanaagsan) | ku haboon (wanaagsan) | -40~107℃ | 107℃ | 176℃ | Hydrogen chloride oo xoog leh |

| Teflon caag ah (PTFE) | wanaagsan | wanaagsan | wanaagsan | wanaagsan | 0.35 ~ 3.0mm | max34.5 daq14.5 | max34.5 daq14.5 | 40% | 5% ilaa 8% | 5% ilaa 10 | Inta badan gaaska daxalka ah dareerayaasha organic | ku haboon (wanaagsan) | ku haboon (wanaagsan) | ku haboon (wanaagsan) | ku haboon (wanaagsan) | ku haboon (wanaagsan) | ku haboon (wanaagsan) | ku haboon (wanaagsan) | -250 ~260 ℃ | 260℃ | 371℃ | Iska caabbinta xirashada liidata |

| Fluororubber(FKM)/Viton | wanaagsan | wanaagsan | wanaagsan | celcelis ahaan | 0.7 ~ 3.0mm | max34.5 daq14.5 | max34.5 daq14.5 | 50% | 10-20% | 5-15% | gaasta daxalaysa dareerayaasha organic gaaska guud | ku haboon (wanaagsan) | ku haboon (wanaagsan) | ku haboon (wanaagsan) | ku haboon (wanaagsan) guud | miskiin | ku haboon (wanaagsan) | celcelis ahaan | -250 ~240 ℃ | 240℃ | 287 ℃ | ammonia |